INTRODUCTION:

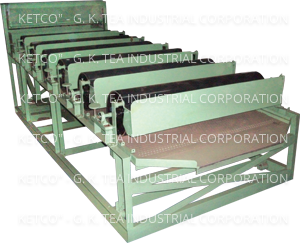

In the sixties, Tea Fibre extraction was done but it was a big task. During early seventies, experiments started with plastic pipe, on the theory of static electricity. An additional device was provided to elector-magnetize the PVC pipe. It was designed as Rollers, which move at a slow RPM.

In due course these Rollers of PVC pipe of higher diameter, moving on very slow speed, helped to extract more fibre from bulk teas. The experiment practically struck to a point of satisfaction and Tea Industry accepted the equipment largely. It was thus named the Fibre Extractor. GK Tea Industries is one of the pioneers in Jumbo & standard Fibre Extractor & tea sorting/grading machine manufacturers.

ADVANTAGES:

- It does not rub or crush the teas. Hence the bloom remains unaffected.

- It does not "GREY" the teas.

- Operating lever for adjustments of rollers has a wide scope.

- Rollers can be adjusted even when the machine is running.

- Separate drive is not required for a feed conveyor as it is provided with the machine.

HOPPER:

Hopper is fabricated out of M.S. or Stainless Steel (304) sheet with adequate support Brackets mounted on the main frame of the machine. The hopper can be fitted with a Presorter (OPTIONAL - Costs extra). A wooden frame with wire mesh no. 6 or 4 with a chute is fitted below the feed hopper. The frame works as PRESORTER and separates bulks, cakes and unwanted particles.

NOTE:

Option of Trinick Sorter without PVC Rollers fitted with desired Stainless Steel Wire mesh is also available. Do specify if your requirement matches this specification.

Maintenance:

- Greasing is required only in the Main Big End housing every 3 months and oil lubrication is required on link chains.

- Felts described earlier, require replacement when torn, generally once after six months if the machine works daily full time.

- The outer surface of PVC Rollers becomes scratchy and generally fine grooved after prolonged use. It is a very slow process. In such circumstances the rollers should be placed on lathe and trued to level and re-used.

Technical Data

|

Power |

2.66 KW/2 H.P. |

|

Capacity |

800 Kgs/hr for 36" Fibre Extractor |

|

Floor Area |

2706 x 1200 MM |

|

Height |

1330 MM. |

|

R.P.M |

250 for the tray & 19 of the PVC Rollers |

|

Models |

36" X 4 Rollers; 36" x 6 Rollers; |